The welding completeness of the body-in-white panels, as the main component of the vehicle, is the key to the efficiency of the body-in-white production. Intelligent manufacturing is receiving more and more attention from various countries 1.

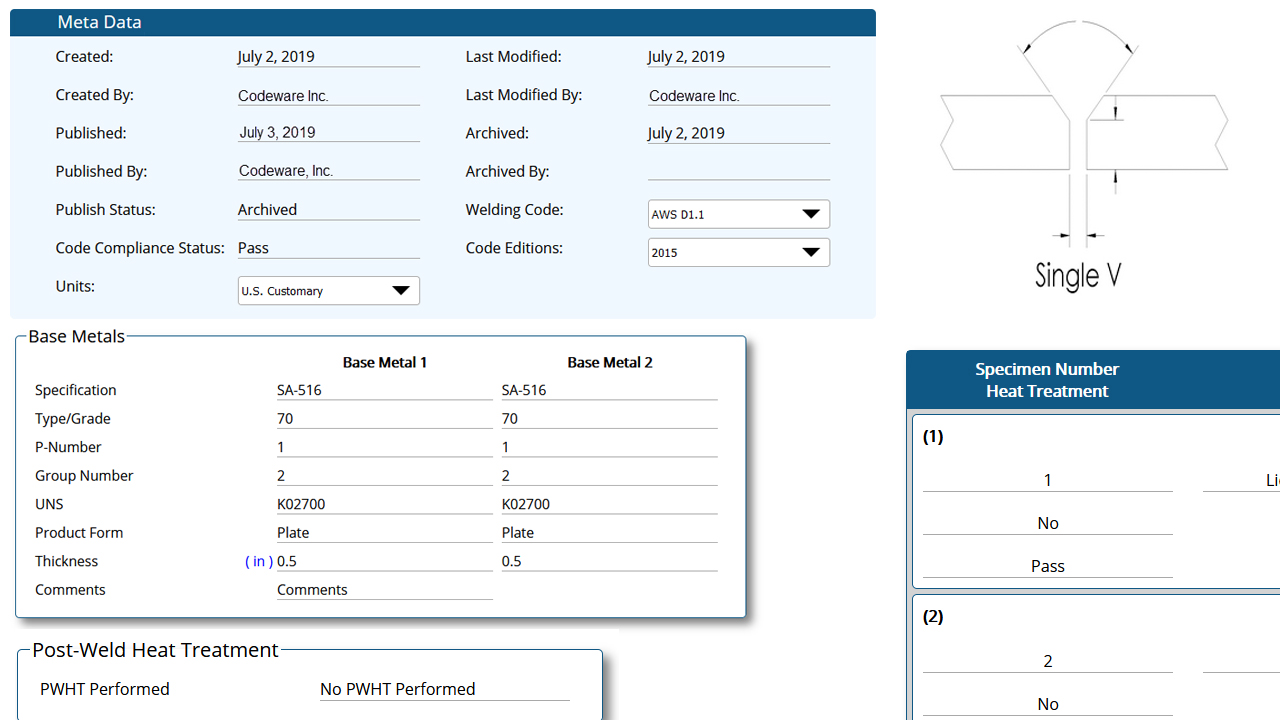

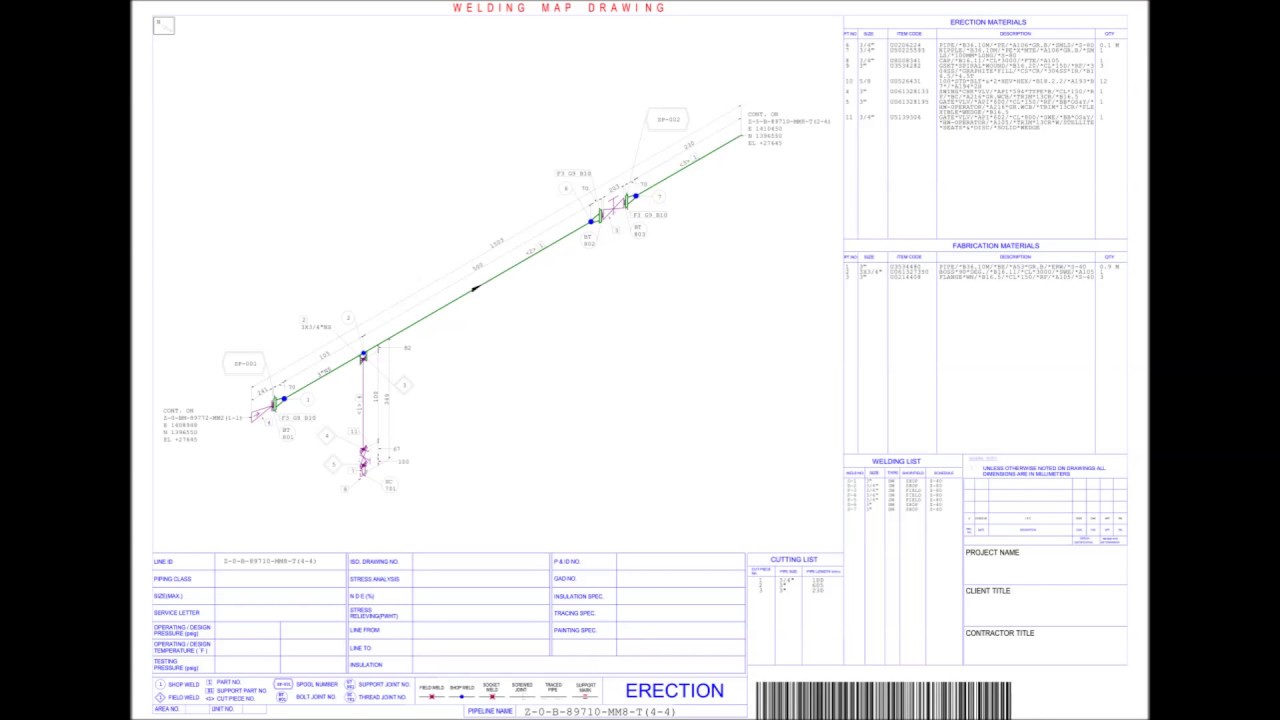

That symbol shall be marked at each pressure containing weld, or an adjacent area to the weld.With the rapid development and application of a new generation of information technology, the global manufacturing industry is accelerating toward digitalization, networking, and intelligence. Where do you put the identification symbol on a weld?ĪSME Boiler and Pressure Vessel Code, Section IX, and ASME B31.3 require that each qualified welder and welder operator be assigned an identification symbol. A weld map is laid out based on the two following features. As a matter of fact, both of those are separate components of the metal fabrication process. Weld mapping is also sometimes called weld tracking or welding traceability and is usually confused with fabrication drawings. How is a weld map different from a fabrication drawing? The WPS 02 will be used for head to shell joints. The WPS 01 will be used for longitudinal and circumferential joints. The following sketch illustrates a typical pressure vessel weld map and indicates 4 WPS’s are going to be used for manufacturing of this pressure vessel. What is the welding map for a pressure vessel? Weld maps, if done correctly, can be of tremendous help in the event problems develop with quality issues or service-related issues. Welding maps are used to track location, size (length and depth) and welder ID associated with repair welds. What do we need to know about welding maps? There are five basic welding joint types commonly used in the industry, according to the AWS: In short, a PQR serves as evidence that a given WPS can, in fact, be used to produce an acceptable weld. The procedures for creating and testing the sample welds, as well as the final results, are documented on a Procedure Qualification Record, or PQR. The PQR is a standard document, but the people who use it may not necessarily come from the same background. A WPS and PQR are mandatory documents when welds need to comply to a standard. In case you are wondering, a WPS stands for ‘welding procedure specification’ and a PQR is ‘procedure specification record’. A WPS is supported by a Procedure Qualification Record (PQR or WPQR).

#WELD MAP SOFTWARE CODE#

What is WPS in welding PDF?Ī Welding Procedure Specification (WPS) is the formal written document describing welding procedures, which provides direction to the welder or welding operators for making sound and quality production welds as per the code requirements. Genuine MAPP gas can be used in combination with oxygen for heating, soldering, brazing and even welding because of its high flame temperature of 2925 ☌ (5300 ☏) in oxygen. It brings serious risk of electric shock from the arc that extends between the electrode and the base material used to fuse materials together. What type of welding is used for pipelines?Īrc welding is the most common type of welding and is a daily activity at pipelines.

#WELD MAP SOFTWARE MANUAL#

This concept of a worksheet filled with fields on a repetitive, manual task is common across many other documents in a production environment, not only the welding industry. Traditionally, operators have used a “weld log”- a paper sheet with fields for data points on each weld. The welding procedure specifications (WPS’s) are provided by the manufacturer to the customer for approval. The welding map is the equipment sketch which identifies the welding seams and indicates what welding procedure specification (WPS) shall be used for that particular welding seam. See the weld map example below this example includes nine welds and two segments or piping spools. The process of numbering or annotating each weld’s location is what turns the standard drawing into a map. A weld map is a version of the drawing used to number each of the welds or joints contained within it.

0 kommentar(er)

0 kommentar(er)